Specialized Technology

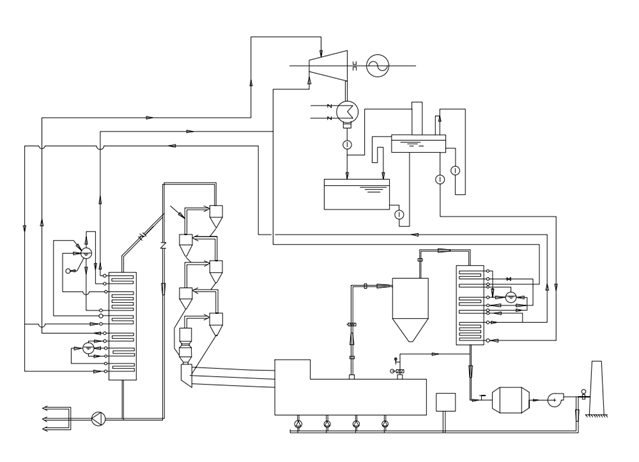

(I) Complete Process System for Cement Kiln Waste Heat Power Plant & Equipment Retrofit Technology

(II) Adjustable Waste Heat Boiler

This technology is designed for AQC waste heat boilers at the kiln inlet. When the air intake temperature exceeds 425°C, it ensures more stable boiler operation and extends superheater service life.

(III)Integrated Kiln Hood (IKH)

This technology integrates the settling chamber and the waste heat boiler into one unit, enabling a small footprint and low investment

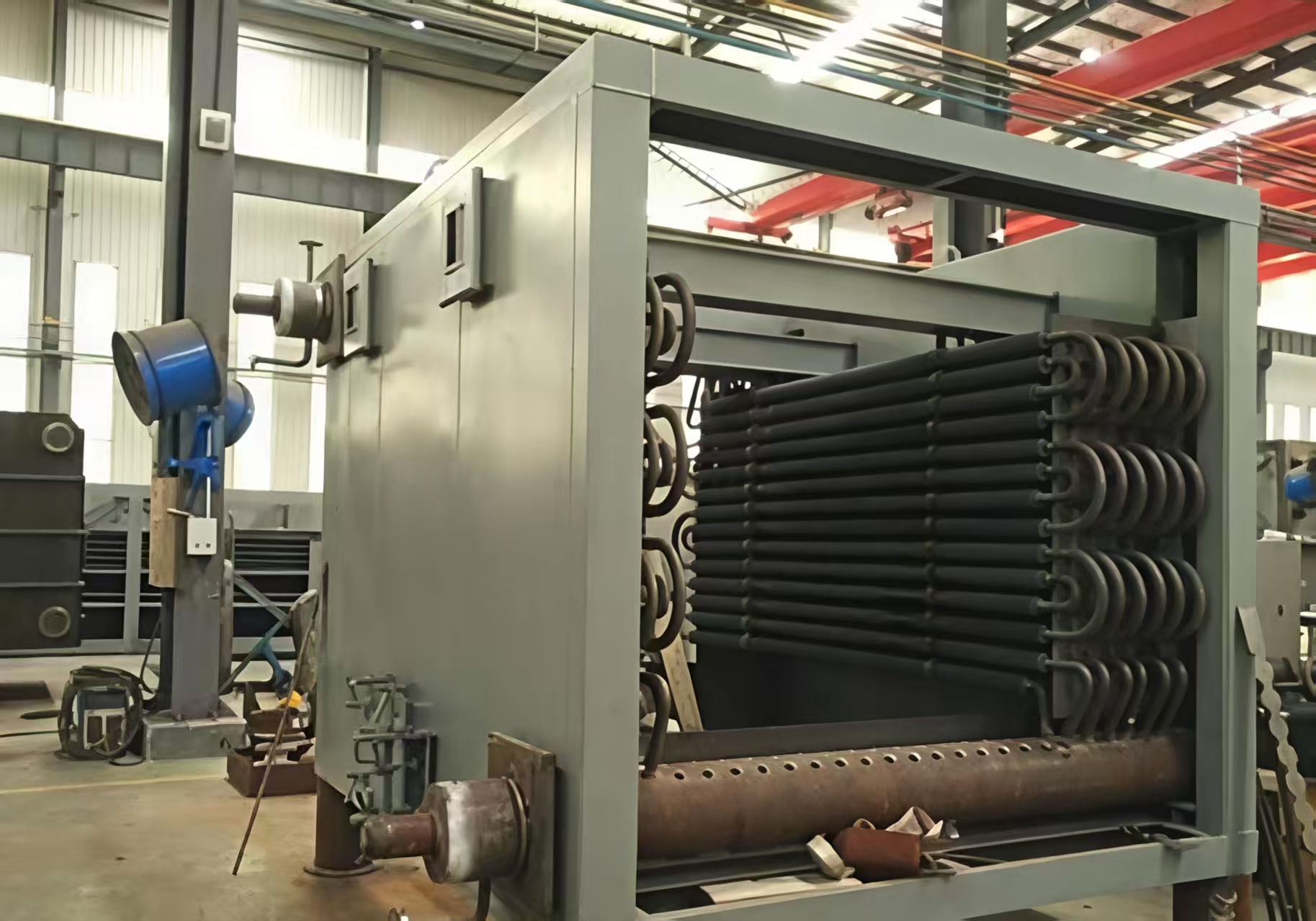

(IV)Modularity

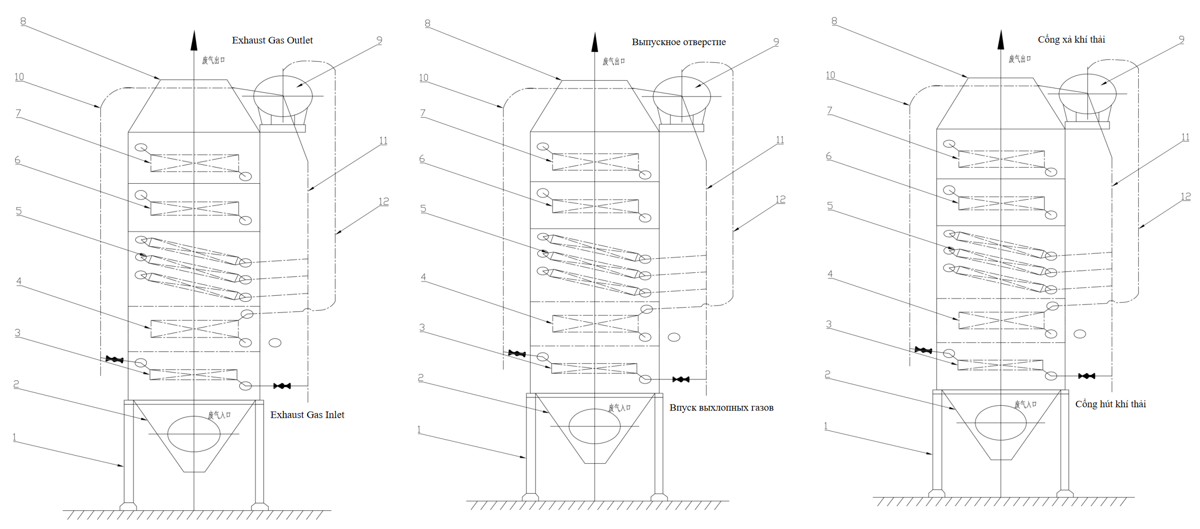

This technology enables the modular supply of the SP waste heat boiler at the kiln exit, reducing its installation time by over 60% and ensuring higher reliability in boiler welding quality

(V)Radiation heat recovery and utilization process, equipment technology and products for cement kiln shell.

It can provide hot water for daily bathing and domestic use of cement plant employees, and realize heating for the plant's office areas, making it a green and energy-saving project.

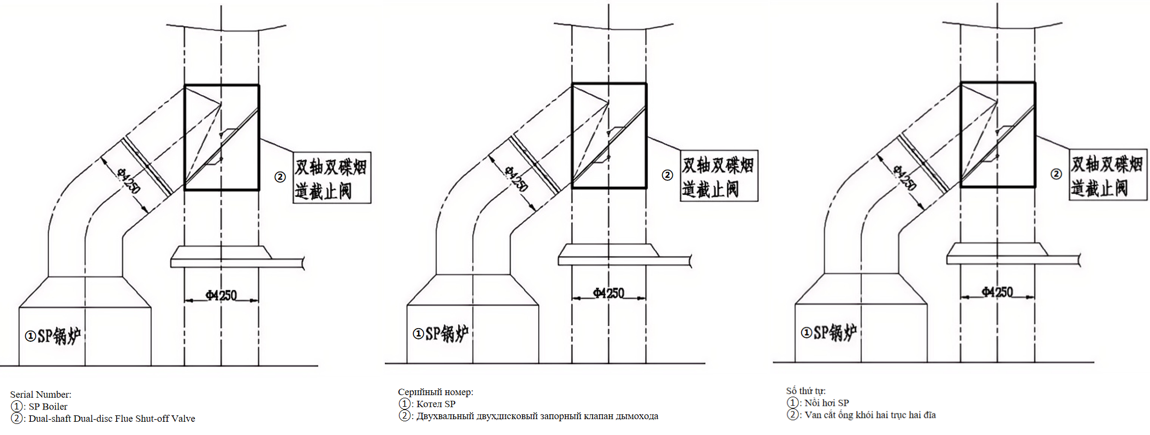

(VI) Kiln tail bypass valve (dual-shaft dual-disc valve)

(VII) Kiln tail bypass air discharge waste heat recovery and utilization process, equipment technology and products

1)Enhance power generation capacity of waste heat power stations: For a 5,500 t/d cement clinker production line, when the bypass air discharge rate is 5%–8%, the power generation capacity can be increased by 700 kW–1200 kW;

2)Enable the utilization of low-grade raw materials and fuels, and expands the sources of raw materials and fuels (reducing fuel and raw material costs);

3) Discharge over 50% of Cl⁻ out of the process system, solve the problem of crusting and blockage in the kiln tail smoke chamber, calciner and preheater, and create basic conditions for treating waste with cement kilns without affecting clinker quality.

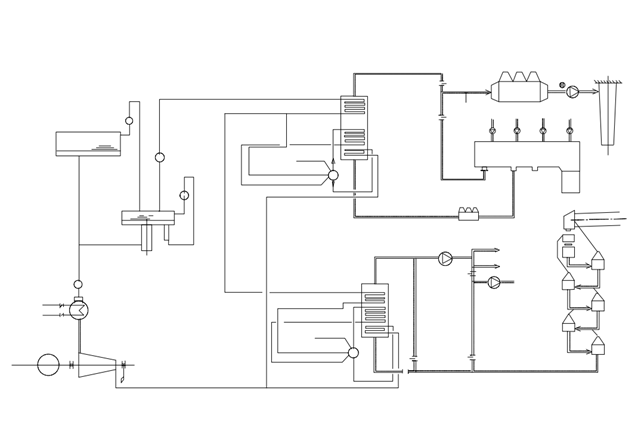

Dual/Single-pressure system for waste heat power generation

Features:The waste heat boilers at the kiln head and kiln tail are both single-pressure boilers. The kiln tail boiler has a minimum exhaust temperature of approximately 190°C, while the kiln head boiler has an exhaust temperature of around 87°C. It has relatively lower waste heat recovery efficiency but requires the least investment.

Dual-pressure system for kiln tail and single-pressure system for kiln head

Features: The waste heat boiler at the kiln head is a single-pressure boiler, while the one at the kiln tail is a dual-pressure boiler. The exhaust gas temperature of the boiler at the kiln tail is around 175°C, and that of the boiler at the kiln head is about 87°C. Compared with (1), its waste heat recovery efficiency is approximately 10% higher, and the investment cost is roughly 6% higher.