Confronted with the "carbon peaking and carbon neutrality" policy constraints and growing industry competition, cement production lines are in urgent need of systematic renovation to meet the three key objectives of energy consumption reduction, production capacity improvement and environmental compliance. Focusing on the key links of the entire cement production process, this project adopts a combined plan of "equipment upgrading + process optimization + intelligent management and control" to help enterprises reduce comprehensive energy consumption by 10%-30%, increase clinker production capacity by 10%-30%, meet the latest environmental emission standards, and promote green and low-carbon transformation. Customized solutions for each enterprise: Based on the existing equipment of cement plants, regional resources (such as sources of biomass and industrial hazardous waste) and policy requirements, provide "plant-specific" renovation solutions.

Full-lifecycle service

Design, equipment procurement, construction and installation, commissioning and training, as well as post-operation maintenance are covered, ensuring stable operation up to standards after renovation.

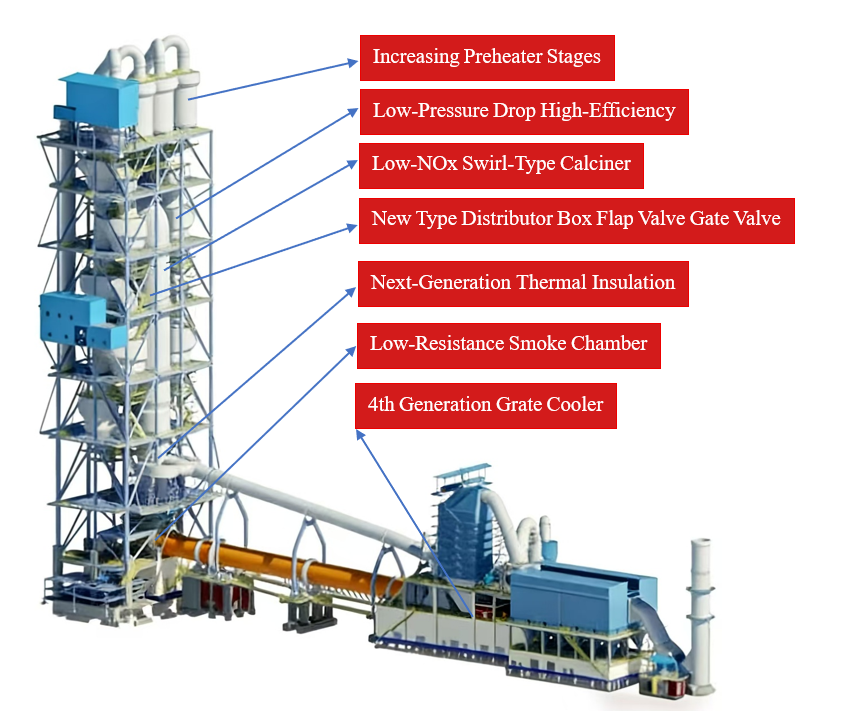

Core renovation fields and key projects:

Firing system renovation:

| No. | Key Points for Consumption Reduction | Technical Measures | Expected Reduction in Comprehensive Coal Consumption |

| 1 | Control fuel combustion |

Increase the calciner's volume Optimize the ways of feeding air, materials and coal into the furnace Optimize the fuel combustion control in the kiln |

Decrease by 0.8–1.2 kg/t.d |

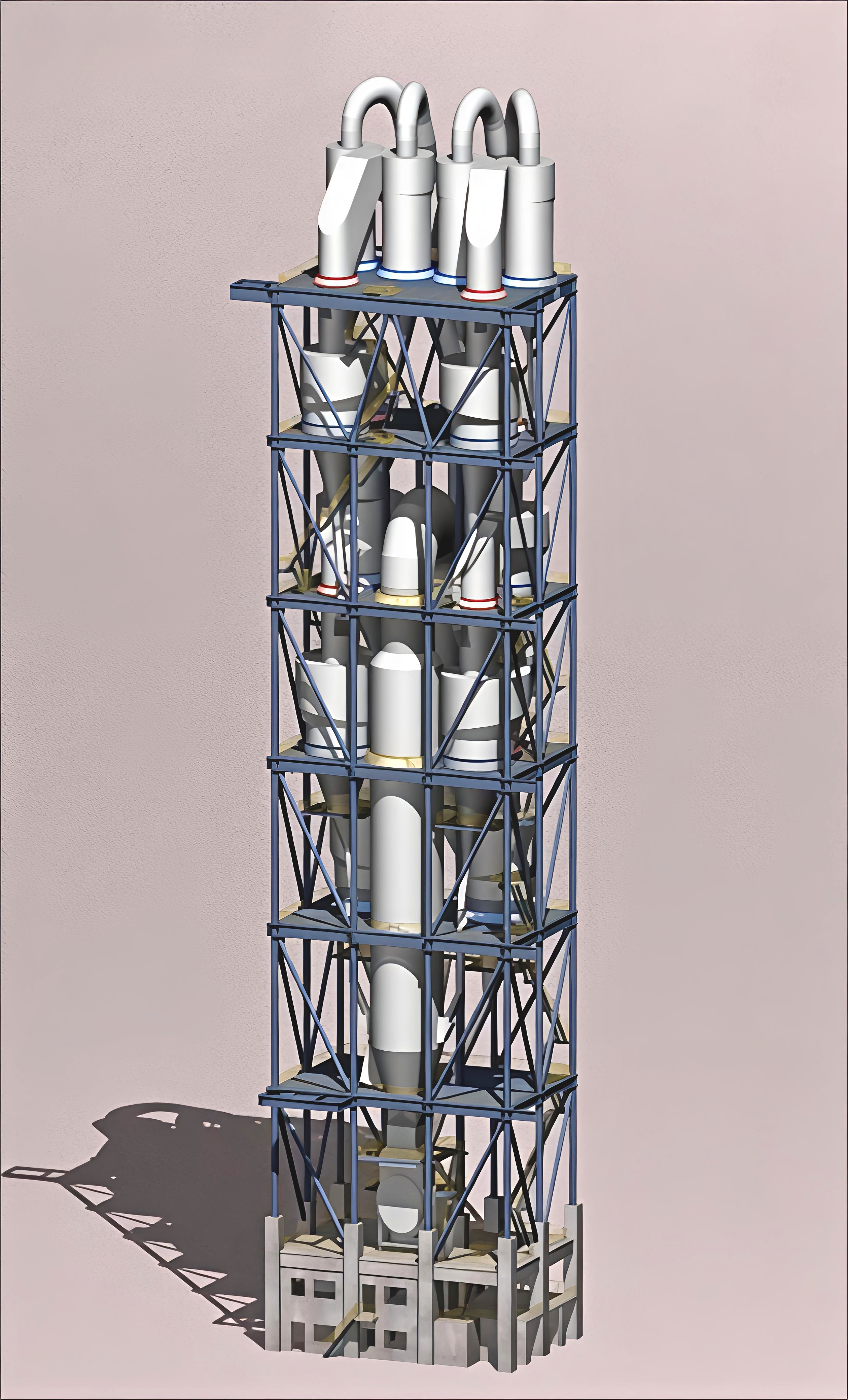

| 2 | Improve the thermal efficiency of the preheater, i.e., enhance the heat transfer from materials in the Cn-1 cyclone |

Improve the separation efficiency of the cyclone Strengthen gas-solid heat transfer Appropriately control the outlet temperature of the calciner at a relatively low level |

Decrease by 1–2 kg/t.d |

|

Transform the five-stage preheater into a six-stage one |

Decrease by 3–4 kg/t.d | ||

| 3 | Improve the thermal efficiency of the grate cooler |

Control air leakage in the system Control the coal feeding air volume and primary air volume |

Decrease by 0.2 kg/t.dl |

| 4 | Control the cold air entering the system |

Replace with the 4th-generation grate cooler Optimize the front-end air distribution Optimize the air extraction position for AQC furnace |

Decrease by 0.5 kg/t.d |

| 5 | Reduce heat dissipation from equipment surfaces |

Use heat-insulating materials and kiln bricks with low thermal conductivity Apply external thermal insulation to the connecting pipes of C1 and C2 |

Decrease by 1.5–2.5 kg/t.d |

| 6 | Improve the burnability of raw meal and reduce the heat required for clinker formation |

Optimize the mixing scheme |

Decrease by 1.5 kg/t.d |

| 7 | Introduce air and material preheating technology into the system | Make use of waste heat for increasing the temperature of primary air and raw meal fed into the kiln | Determine based on actual conditions |

| 8 | Reduce the back-mixing degree of solid materials in the system | Replace with a low-resistance smoke chamber | Determine based on actual conditions |