Introduction:

NOₓ ultra-low emission renovation refers to reducing the emissions of nitrogen oxides (NOₓ) through a series of technical measures and equipment upgrades, in order to meet environmental protection requirements and emission standards.

The achievement of NOₓ ultra-low emission renovation relies on advanced waste gas control equipment and technologies, such as denitration technology, SCR (Selective Catalytic Reduction) technology, and SNCR (Selective Non-Catalytic Reduction) technology. These technologies can effectively convert NOₓ into harmless nitrogen and water vapor, thereby reducing the emission concentration and meeting the ultra-low emission standards.

In addition, the NOₓ ultra-low emission renovation also requires the optimization and control of the combustion process, including adjusting parameters such as combustion temperature, oxygen content, and fuel type to reduce the formation of NOₓ.

The significance of NOₓ ultra-low emission renovation lies in reducing the concentration of NOₓ in the atmosphere, thereby alleviating air pollution and mitigating harm to human health. Meanwhile, it can also improve energy utilization efficiency, reduce energy consumption and production costs. This holds significant importance for realizing sustainable development, promoting the growth of the environmental protection industry, and addressing climate change.

Characteristics of NOₓ ultra-low emission renovation:

- High-temperature technology

- High-efficiency SNCR

- Low investment

- Mature technology, up to 50 mg/nm³@10% O₂

Reburn zone denitration technology

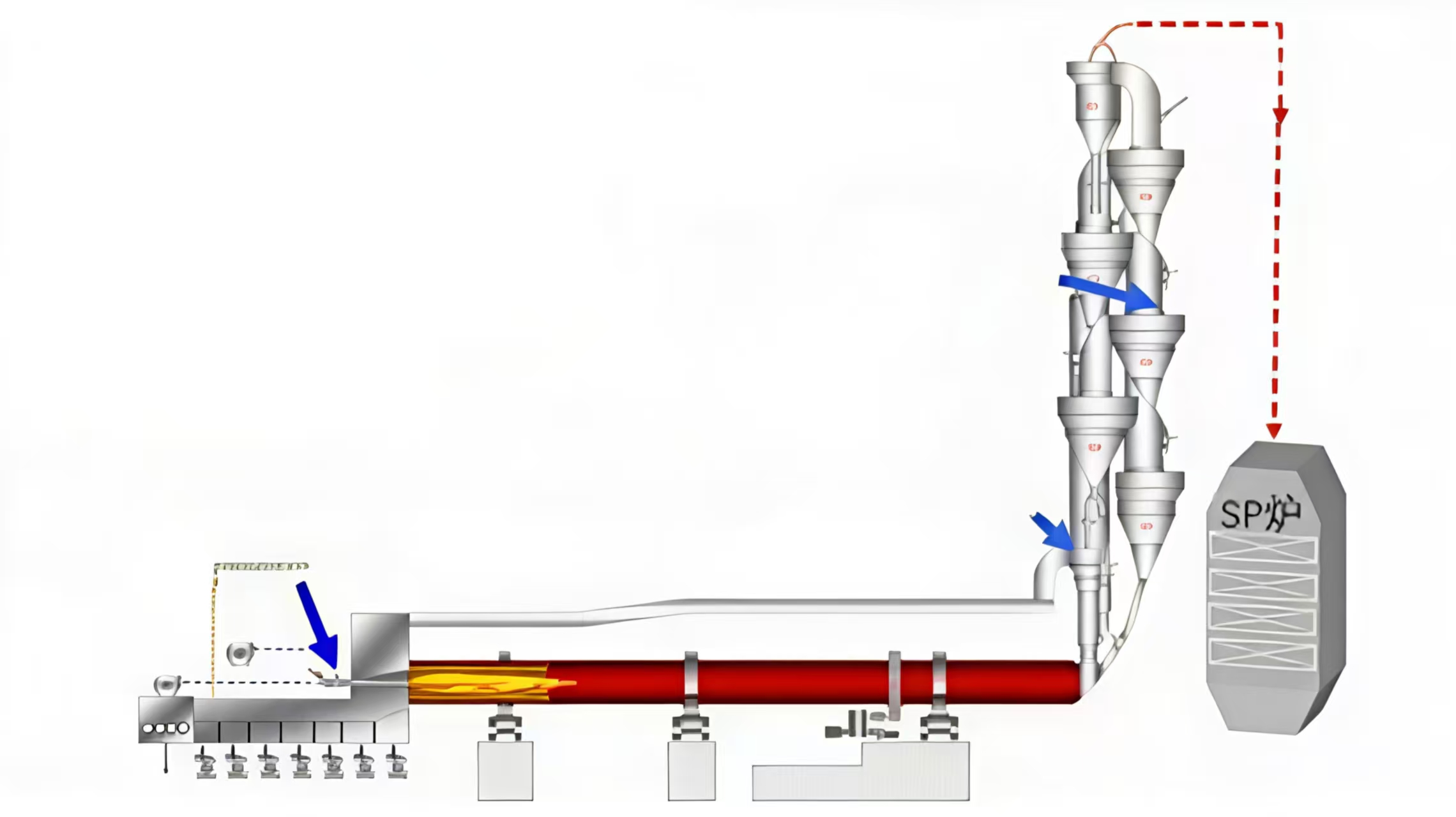

Technical route for ultra-low NOₓ emissions in cement kilns:

Low-NOₓ burner -> Reburn zone denitration technology -> High-efficiency technology

Principle of reburn zone denitration technology:

By creating a reductive combustion zone between the smoke chamber and calciner, the reburn zone denitration technology realizes oxygen-deficient combustion, which produces reducing agents including CO, CH₄, H₂, HCN, and fixed carbon. These agents then react with NOₓ in the kiln tail flue gas, reducing NOₓ into non-polluting inert gases such as N₂. In addition, the combustion of pulverized coal under oxygen-deficient conditions also inhibits the generation of fuel-type NOₓ from the coal itself. This results in a compound and synergistic deep denitration solution that combines the denitration reduction furnace with SNCR denitration technology.

The basic principle of the reburn zone denitration technology is to reduce NOₓ in the flue gas of the cement rotary kiln through a one-step Boudouard reaction, where 70% to 100% of the pulverized coal for the calciner is directly fed into the newly added reduction furnace equipment (denitration reduction furnace). Since the oxygen content in the denitration reduction furnace is extremely low (oxygen comes only from the waste gas of the kiln tail smoke chamber), the pulverized coal undergoes high-temperature pyrolysis and gasification reactions therein to generate high-concentration CO. Meanwhile, CO₂ from the kiln waste gas reacts with the residual carbon in the pulverized coal to form CO, which can reduce NOₓ in the kiln gas into non-polluting N₂ with stable properties. The concentration of the reducing medium (CO) and the reaction temperature in the reduction zone play a key role in the denitration reaction. Under strong reducing conditions, the conversion of nitrogen elements in fuel to nitrogen oxides can be effectively inhibited.

Technical advantages

- High efficiency (NOₓ≤50 mg/nm³@10% O₂)

- Low ammonia consumption (less than 3.5 kg/t.cl)

- No additional operating costs

- Low investment

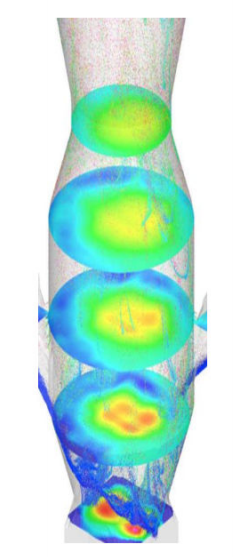

- Appropriate reductive space

Residence time approximately of 2s at a height of 12 m - Reaction kinetics (high-temperature reduction reaction zone technology)

- High temperature can accelerate the reaction rate

>Injection of all pulverized coal at the kiln tail into the reduction zone

>Reduction of NOₓ generated at the kiln head

>Lower NOₓ generated from the combustion of pulverized coal itself - Crusting is prone to occur under high-temperature conditions

>High-temperature core area concentration technology

>Furnace wall low-temperature protection technology

Technical features

- Reburn denitration zone technology

- Calciner intensified combustion technology

- Pulverized coal comb-shaped dispersion technology

- SNCR precise denitration technology

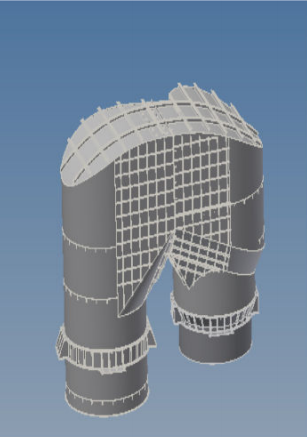

Calciner intensified combustion technology

1、"Mixing is burning" theory.

2、Conventional gooseneck pipes are replaced with eddy current elbows in the design to enhance mixing and ensure full combustion of CO(complete oxidation reaction).

3、It provides favorable reaction conditions for the downstream SNCR and reduces the consumption of ammonia.

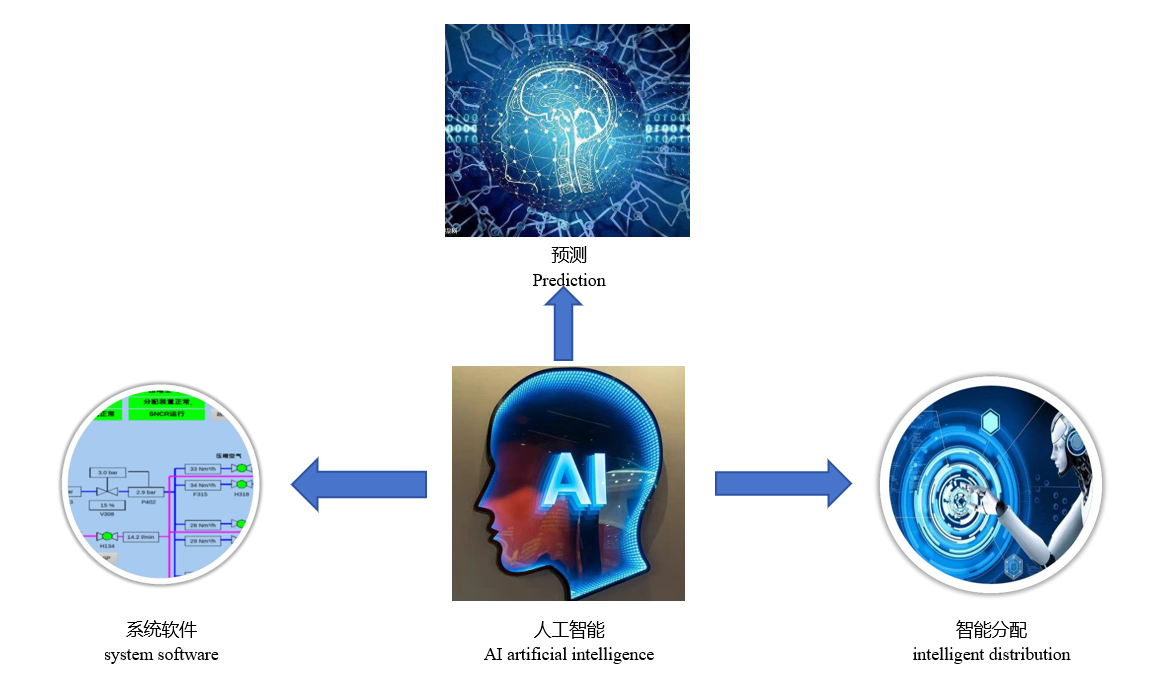

High-efficiency intelligent denitration system

I. Introduction

By applying artificial intelligence and precise control technologies, the high-efficiency and precise denitration project aims to reduce nitrogen oxide emissions, optimize denitration efficiency to the maximum extent, enhance the atmospheric environment, and provide strong support for ultra-low emissions and green manufacturing in the process industry!

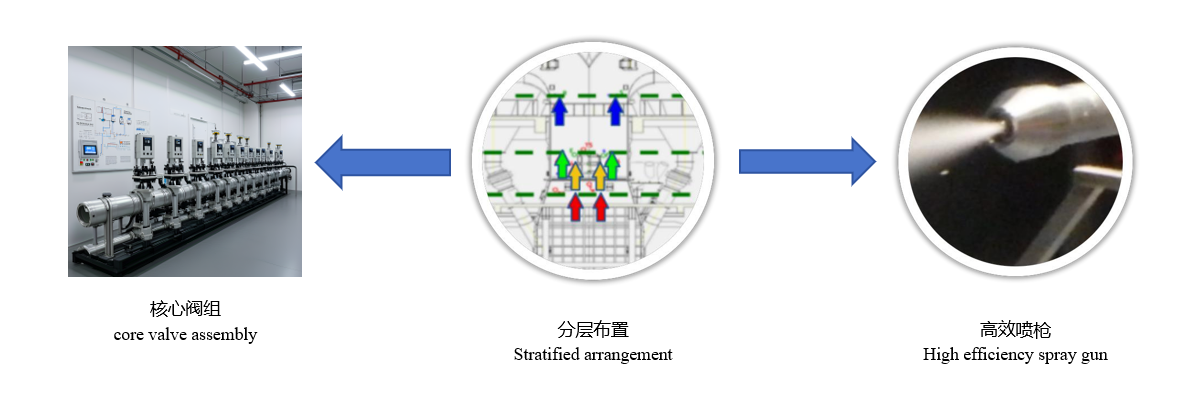

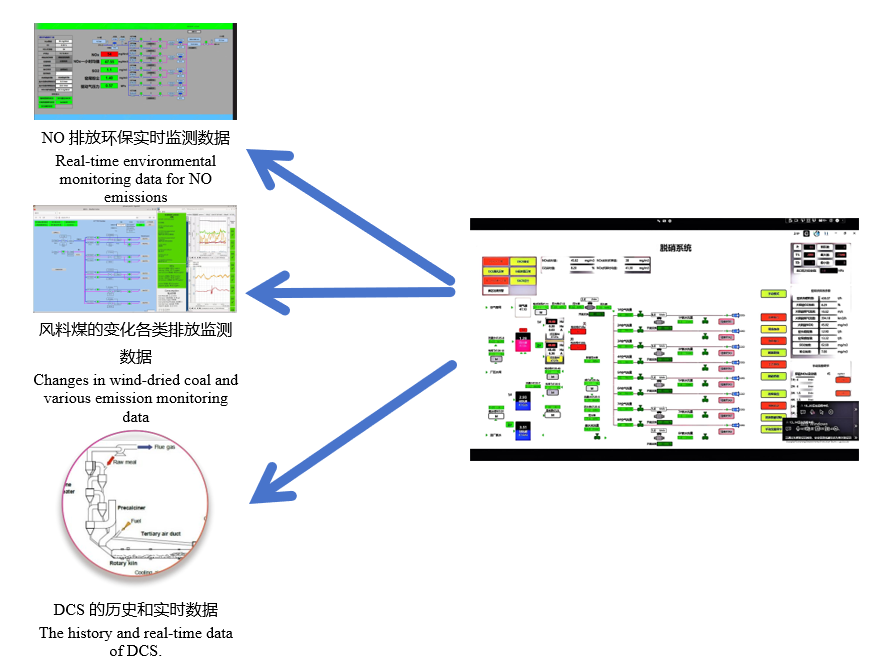

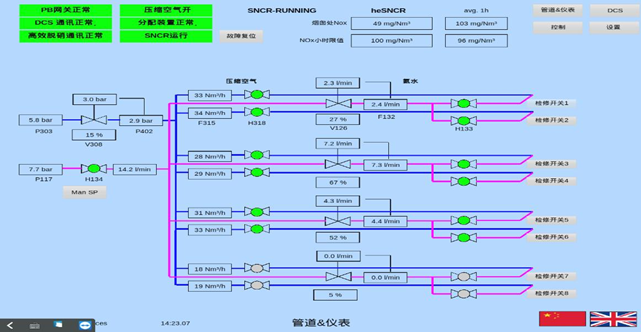

The high-efficiency intelligent denitration system is an ammonia injection system, mainly consisting of the ammonia distribution system (located downstream of the ammonia pump in the denitration system), the spray gun system, and the intelligent advanced control system. The control software, as the core of the system, consists of the optimization control system, prediction system, and ammonia distribution optimization model; while the executive hardware comprises high-precision spray guns and distribution valve groups used for the accurate control of the spray guns.

II. System composition

Software

Hardware

III. Advantages

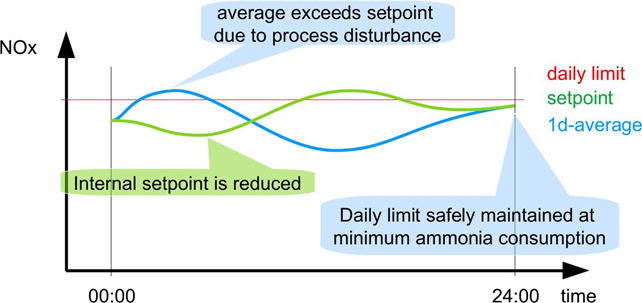

- Intelligent prediction system:

Model training, review and calibration, real-time update, and prediction of nitrogen oxide emission data for the next 3 minutes.

- Real-time optimization system:

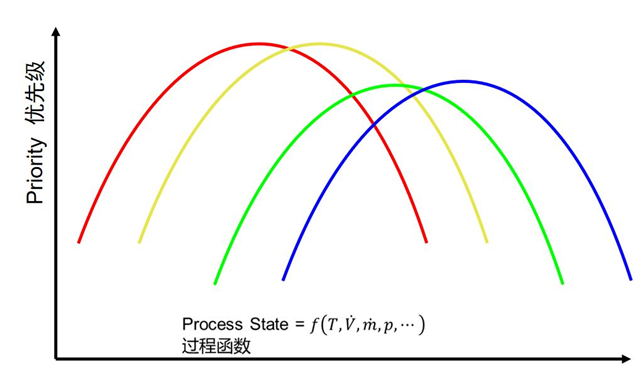

Ammonia is adjusted in real time based on NOₓ emissions, and the system matches and adjusts the compressed air pressure set value according to the performance curve.

IV. Product value

(I) Ultra-low emissions

(II) Reduced ammonia consumption by 20%-60%

(III) Decreased ammonia escape

(IV) Low operating rate

(V) Project implementation:

(I) Advantages

- Customized test and plan for each plant

- Provide a complete set of upgradeable technical routes for implementation

- Reduce the user's overall investment and operating costs

(II) Implementation process

- 1.Data test

Carry professional instruments to conduct detailed on-site investigations and data testing in each branch factory - 2.Plan formulation

Design a future-oriented denitration overall route plan suitable for each factory based on the investigation and test results

Modify the plan based on the owner's comments - 3. Group review

After the completion of the plan design for all branch factories, compile and submit them to the Group for review - 4.Project implementation

Implement the project in accordance with the Group's review comments and combined with the actual situation of each factory