Introduction

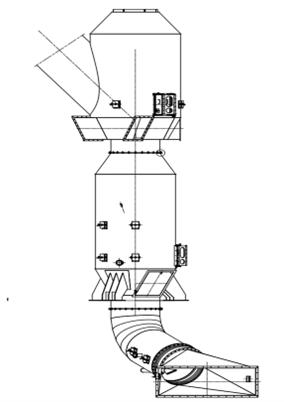

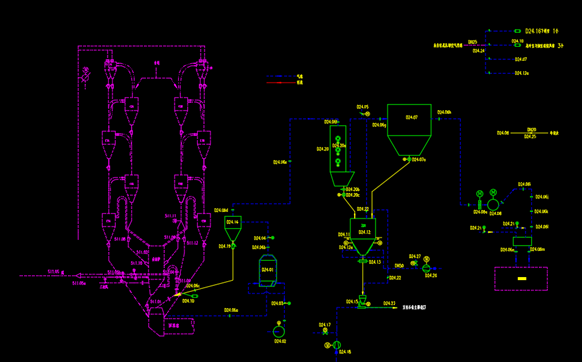

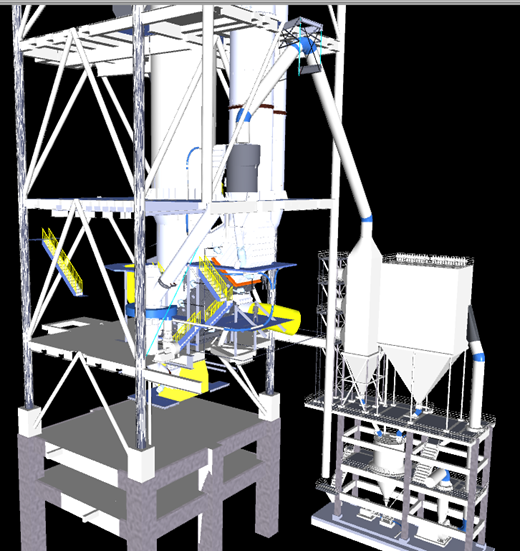

The presence of harmful components (primarily chlorine) in cement raw materials and co-processed wastes raises the control standards for cement production, and it may result in crust formation and clogging in the pre-decomposition system. Therefore, a bypass air outlet is installed on the kiln tail chamber, and bypass air discharge is implemented to expel harmful components such as chlorine, alkali, and sulfur in raw materials or wastes from the firing system. This reduces the cyclic enrichment of harmful components, maintains stable operating conditions of the kiln system, and meets the needs for long-term safe operation of the equipment. The maximum capacity of the bypass air discharge system is designed based on 5% of the flue gas at the kiln tail. During actual operation, the volume of bypass air discharge can be adjusted via a variable-frequency induced draft fan according to the chlorine content of the hot raw meal fed into the kiln (sampled from the discharge pipe of the C5 cyclone). The bypass air discharge system comprises processes of extracting flue gas from the kiln tail chamber, mixing in air to quench the flue gas rapidly, separating powder via a coarse powder separator, cooling through a multi-tube cooler, collecting dust with a bag filter, conveying the collected dust to the inlet of the kiln head bag filter by pneumatic means, and introducing the waste gas into the inlets of fans F1 and F2 of the kiln head grate cooler via an induced draft fan.

The bypass air discharge system is designed with a maximum air discharge rate of 5%. During normal operation, it can eliminate the crusting and blockage issues caused by chlorine (Cl) in the system, ensuring the stable operation of the kiln system.

During bypass air discharge, the heat consumption for clinker sintering increases, with a 2.5 kcal/kg-cl rise in heat consumption for every 1% increase in bypass air volume.

Chlorine in hazardous wastes is prone to causing crusting and blockage in the preheater system, which in turn exerts a certain impact on the stability of the firing system. This problem can be solved by adopting bypass air discharge. Chlorine in hazardous wastes has no direct impact on cement clinker. However, since all dust collected by the bypass system is blended into cement clinker, and according to GB175-2007 Common Portland Cement, the chlorine content in cement shall be ≤ 0.06%, it is necessary to control the dust amount or chlorine content of bypass air discharge.

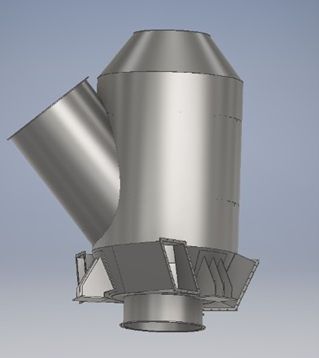

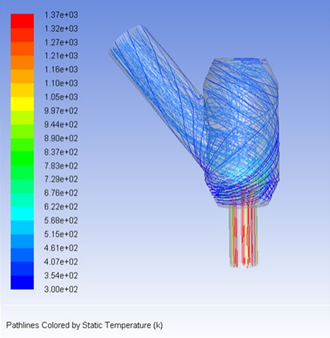

When the bypass system needs to be activated, a portion of the high-temperature flue gas in the kiln tail chamber is extracted through the bypass air outlet and enters the quench chamber, where it mixes with the cold air blown in by the cooling fan. The temperature of the flue gas exiting the quench chamber is controlled at approximately 300°C. Subsequently, the flue gas passes through a cyclone separator, where the coarse particles with low chlorine content are returned to the pre-calciner, while the fine ones with high chlorine content are carried by the airflow. After being cooled by a multi-tube cooler (via forced convection heat exchange with air from the axial flow fan) and purified by a bag filter, the fine particles are discharged by the exhaust fan into the high-temperature section of the kiln head grate cooler, and then sent into the kiln for incineration disposal. The fine dust collected by the multi-tube cooler and bag filter is stored in a dust silo, then transported to the inlet of the kiln head bag filter via a pneumatic conveying system, and finally uniformly mixed into the clinker.

A certain number of air cannons are installed near the kiln tail chamber and air extraction ports to facilitate the removal of crusts.

Objective

Before the cyclic elements (K, Na, Cl, S) in the kiln cause crusting or blockage in the preheater and kiln, these elements (Cl, sulfur, and alkalis) are to be removed. Through cleaning, they can be managed in a controllable manner

- Bypass air discharge: Extract a portion of high-temperature kiln tail flue gas from the kiln tail (unit cycle, location with the highest concentration) to prevent harmful components from condensing in the preheater and causing cyclone blockage.

- Bypass air discharge leads to an increase in the heat consumption of the kiln system;

- The bypass device exhibits the highest efficiency in removing chlorine (Cl), while its efficiency in dealing with sulfur (S) and alkalis is considerably lower;

- After passing through the bypass, the high-temperature kiln gas enters the quench chamber, where it is cooled down by cold air.