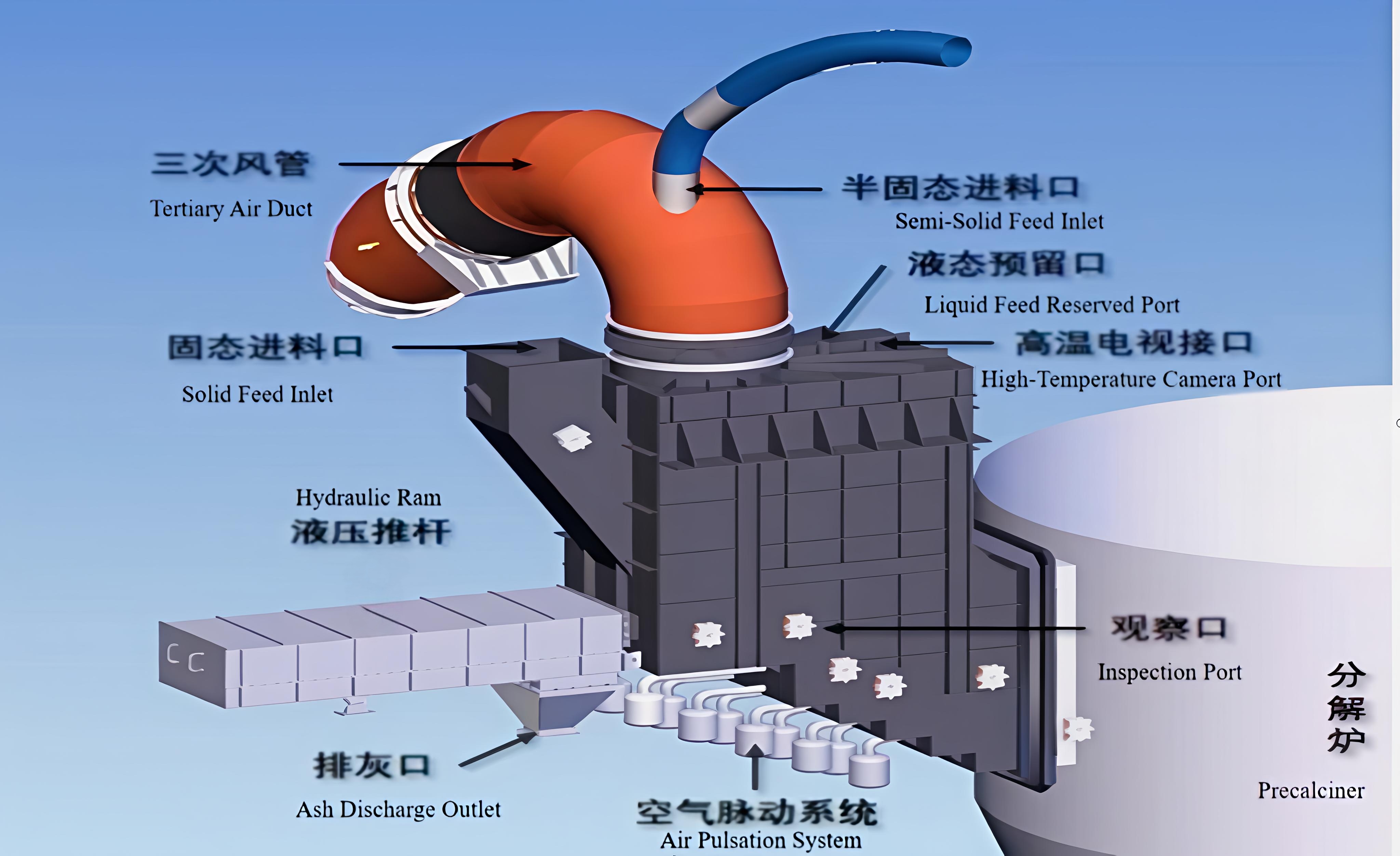

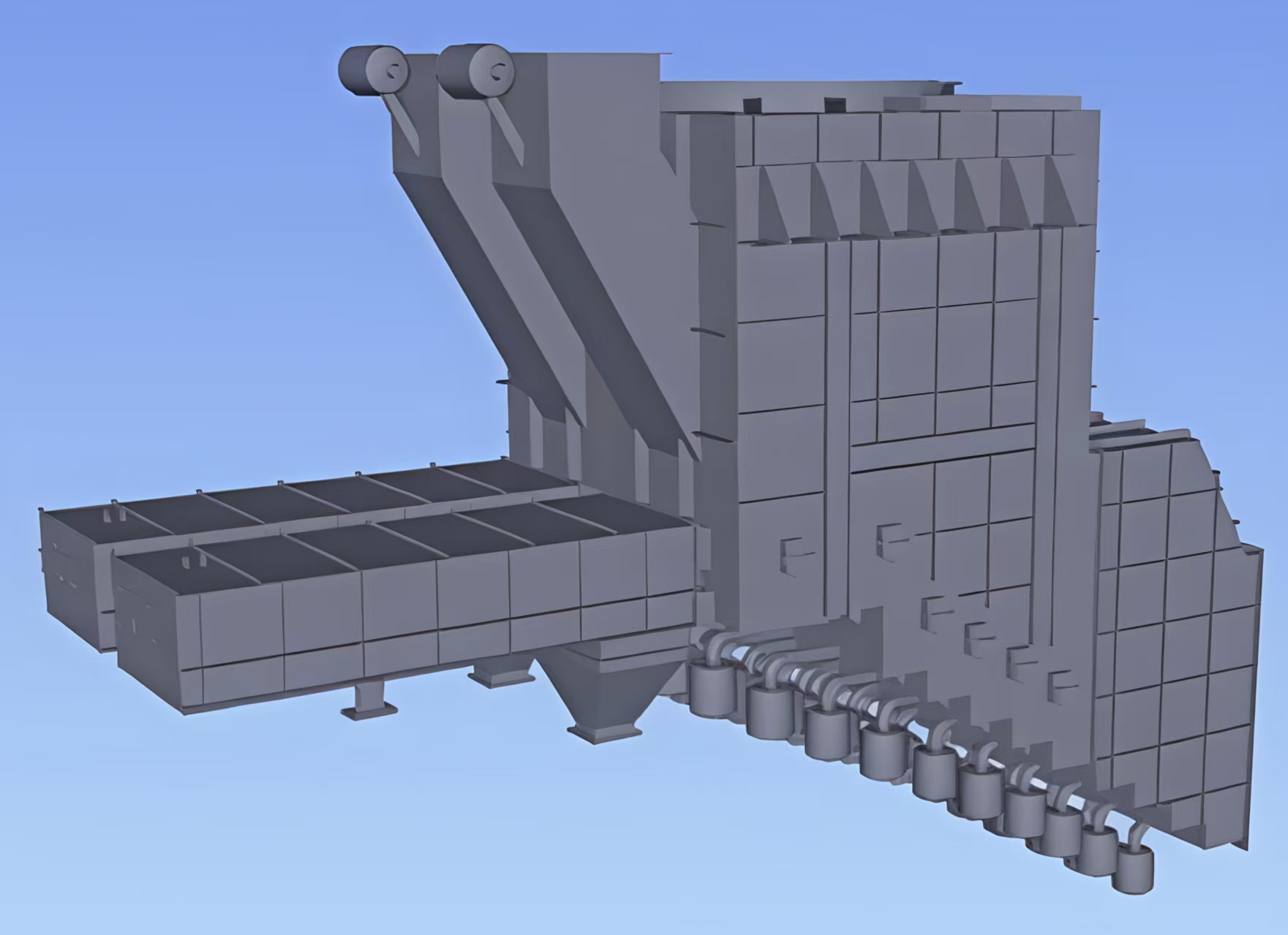

Based on the traditional technology of cement kiln co-processing solid waste (alternative fuel or hazardous waste), the original method of directly feeding solid waste into the calciner is changed to first feeding it into the pre-calciner. After being dried by hot air (tertiary air) and having organic matter burned, the ash residue and flue gas are further fed into the calciner for continued incineration. This further increases the residence time of solid waste in high-temperature incineration inside the cement kiln and significantly improves the high-temperature incineration rate of solid waste. At the same time, it reduces the impact of directly feeding solid waste into the kiln on the quality of cement clinker (such as agglomeration, coating, and yellow-core clinker) and output, and increases the amount of solid waste disposed of by the cement kiln.

1、 Function of the pre-calciner

- After solid waste is fed into the pre-calciner, light materials in it are preheated and pre-combusted, enabling these light materials to burn rapidly once they enter the calciner. As for heavy materials with larger particle sizes and higher density, the pre-calciner facilitates the preheating, drying, ignition and most burnout processes; at the same time, their particle sizes and density will be reduced, which also helps them burn out quickly when they enter the calciner;

- The hydraulic stockpiling platform installed in the pre-calciner is beneficial for relieving the problem of uneven feeding of solid waste. The materials in the pre-calciner are repeatedly blown by air cannons to achieve full dispersion, and finally blown into the calciner via air cannons, which is conducive to the full dispersion and combustion of solid waste in the calciner;

- The adoption of a pre-calciner enables the classification of light alternative fuels and heavy alternative fuels. Light alternative fuels are mainly burned in the calciner, while heavy alternative fuels are mainly burned in the pre-calciner. This reduces the thermal load in the calciner and facilitates the full realization of fuel combustion and raw meal decomposition processes in the calciner.

2、Characteristics of the pre-calciner

- The pre-calciner is composed of a stockpiling platform and multi-stage steps. Materials tumble inside the pre-calciner, enhancing the contact between materials and hot air (tertiary air) and improving the pre-calcination effect;

- The residence time of materials in the pre-calciner can be flexibly adjusted. According to changes in material complexity (moisture content, particle size), the preheating and pyrolysis time of materials in the pre-calciner is controlled by adjusting the frequency of the hydraulic push plate and the blowing frequency of the air cannon, in order to improve the pre-calcination conditions. Temperature can be controlled in multiple operating ways such as adjusting the amount of raw meal, the air volume entering the pre-calciner, and controlling the air cannon;

- The material fed into the pre-calciner is dispersed and effectively distributed across its width. The material fed into the pre-calciner is delivered via a system composed of double air locks and a spiral auger, which ensures excellent sealing effect.

- It has a large solid waste disposal capacity and obvious coal-saving effect, which can greatly reduce the impact on the kiln system.

Engineering case - Pre-calciner for alternative fuels (household waste/waste textiles/biomass)

Engineering case - Pre-calciner for hazardous waste

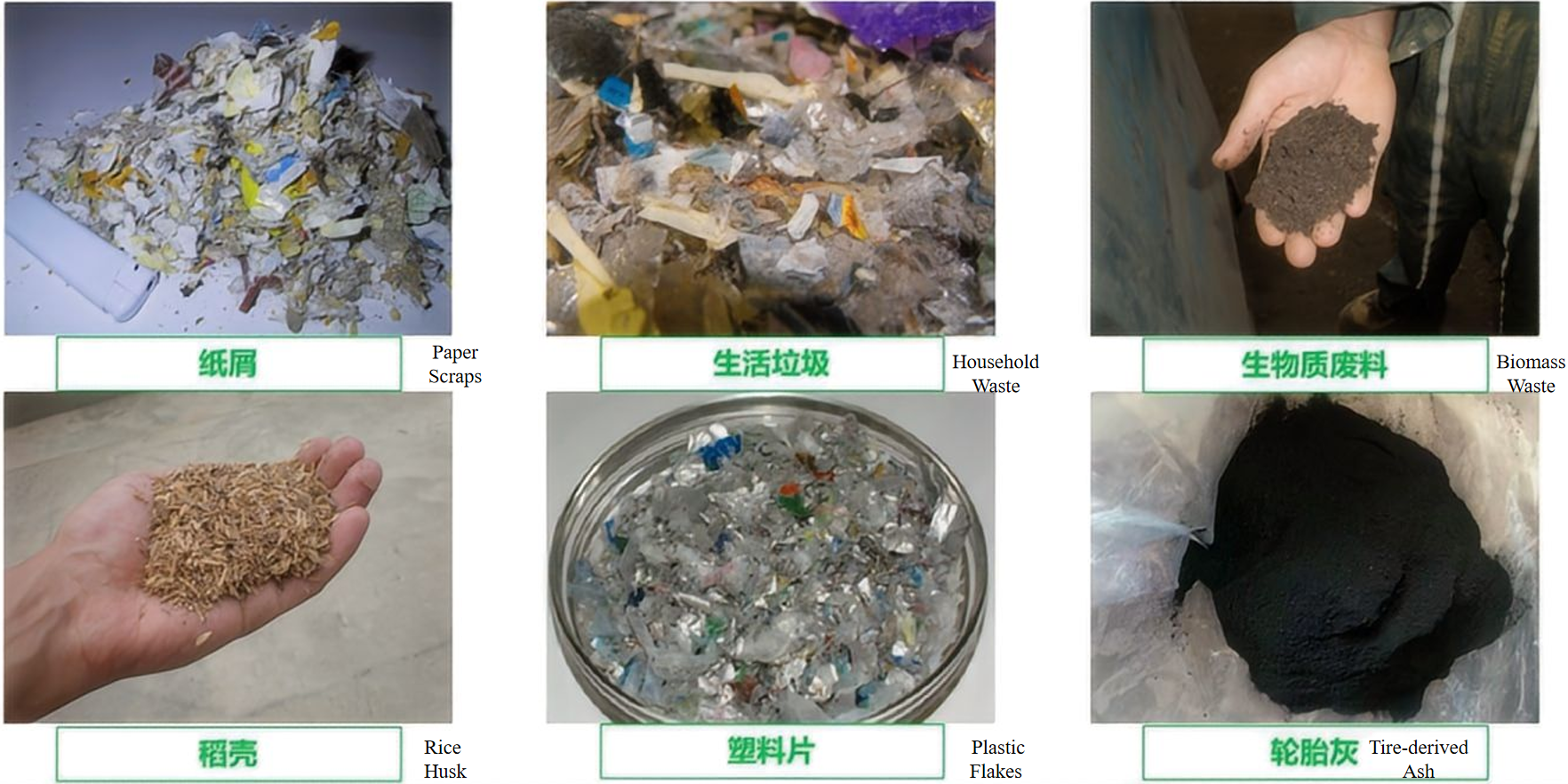

Core functions:One-stop processing of 4 types of typical wastes

Processing of biomass fuel

- It is compatible with agricultural/forestry wastes such as wood chips, straw, and palm kernels, with a wide adaptability to particle sizes, enabling efficient combustion without complex pretreatment.

Co-processing of liquid wastes

- It supports the atomized combustion of industrial waste liquids (such as chemical wastewater, oil-containing wastewater) and waste oils (mineral oils, animal and vegetable oils), realizing the harmless treatment of hazardous wastes.

Efficient energy conversion

- It adopts staged combustion technology, with a combustion efficiency of over 95% and stable thermal output, meeting the strict high-temperature requirements for calcination process of the cement kiln.

Core advantages

- Cost reduction & efficiency improvement: By substituting conventional pulverized coal fuel, it lowers the overall fuel cost by 30%–50% and meanwhile reduces the expenses for outsourcing the disposal of solid/hazardous wastes.

- Environmental compliance: The NOx emission during the combustion process is low, helping enterprises achieve the "carbon peaking and carbon neutrality" goals.

Application value

- Resource recycling: Turning waste into resources, promoting localized consumption and energy utilization of industrial solid waste/biomass resources.

- Industrial upgrading: Helping cement plants transform into "green factories" and enhancing brand competitiveness as well as sustainable development capabilities.