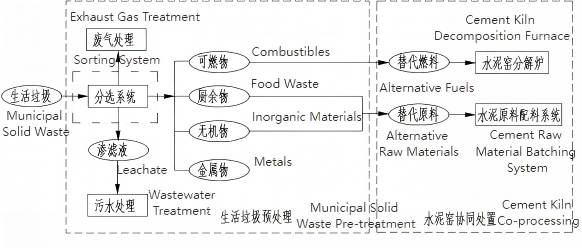

The technology for co-processing municipal solid waste in cement kilns relies on the high-temperature kilns (calciner, rotary kiln) of new dry-process cement production lines to achieve reduction, recycling, and harmless treatment of municipal solid waste. Its core lies in converting waste into alternative fuels and raw materials through pretreatment, which are then integrated into the cement production process. This technology mainly consists of two major links: pretreatment and kiln feeding disposal. In the pretreatment stage, raw municipal solid waste is sorted into combustible materials (such as plastics and paper, with a calorific value of over 10,500 kJ/kg) and non-combustible materials (such as kitchen waste and muck) through processes including coarse crushing, fine crushing, drum screen sieving, magnetic separation and air separation. During kiln feeding disposal, the combustible materials are sent to the rotary kiln or calciner as alternative fuels for high-temperature calcination (with the temperature reaching over 1,450°C), while the non-combustible materials enter the raw mill as alternative raw materials, and the ash residue is finally solidified in the cement clinker.

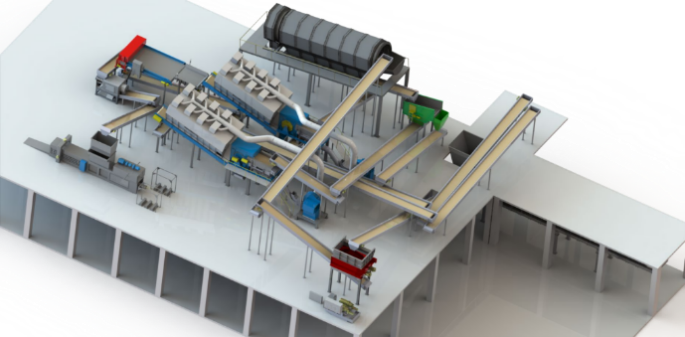

3D models and on-site photos of the solid waste disposal and acceptance system