Introduction:

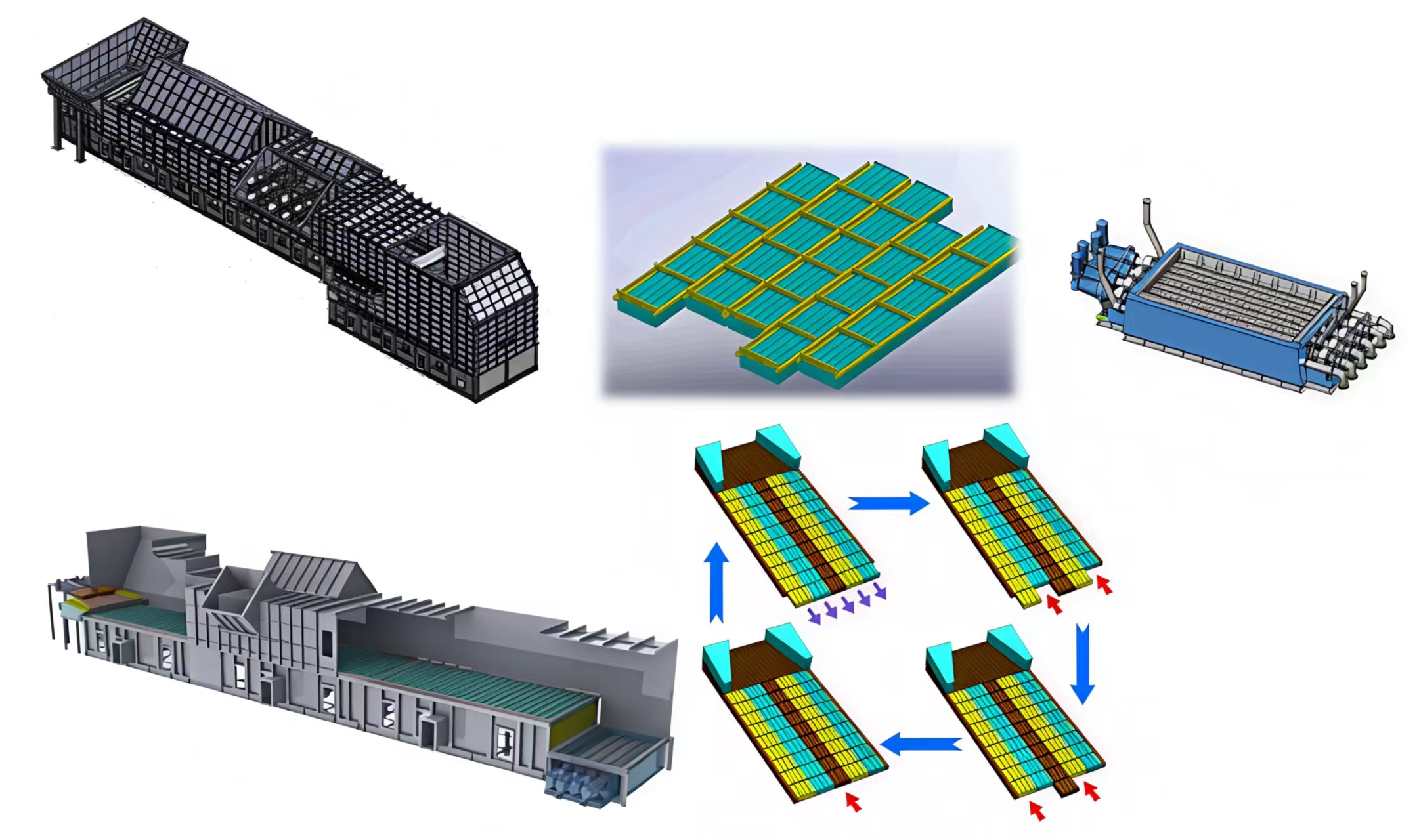

The 4th-generation in-line cooler operates in accordance with the walking-floor conveying principle to realize the horizontal conveying of clinker with a thick material layer, featuring high heat recovery efficiency and low discharge temperature. A fixed grate controllable aeration system is installed at the feed end to achieve rapid cooling of clinker, effectively improving heat recovery efficiency. The movable grate is equipped with a self-regulating flow valve to adjust the cooling air volume in a timely manner, which can effectively adapt to the working conditions where the particle size and thickness of materials on the grate are uneven and improve the utilization efficiency of cooling air. The grate plate adopts clinker self-protection technology, with a service life of more than 5 years. It has a unique longitudinal sealing structure to ensure no material leakage during the operation of the grate. The modular design is adopted to effectively reduce installation and transportation costs. A clinker roller crusher is used, which has a long service life and ensures uniform discharge particle size.

The 4th-generation cooler with a mid-mounted roller crusher can recover the heat from the interior of large clinker lumps, effectively supporting waste heat power generation and ensuring the final discharge temperature. It is highly suitable for situations where there are many large clinker lumps discharged from the kiln.

Technical parameters:

| Output per unit grate area | 41 t/m2.d (max. 46) |

| Unit cooling air volume | < 2.0 Nm³/kg, clinker |

| Secondary air temperature | ≥1150℃ |

| Tertiary air temperature | ≥950℃ |

| Heat recovery rate | 73%~75% |

| Operation rate | 100% (synchronized with rotary kiln) |

| Discharge temperature | 65°C+ ambient temperature |

| Discharge particle size | <25mm |

| Cooling power consumption | 5.5~6kwh/t.cl |

| Clinker crushing | Roller crusher |

Product advantages:

1. The thermal efficiency is high, and the cooling performance is excellent, with the discharge temperature meeting the requirement of 65°C+ ambient temperature;

2. The equipment operation rate is over 98%, with no material leakage from the grate bed, low wear, and basically no maintenance required throughout the year.

3. The grate plate has a service life of more than 5 years, while the longitudinal seal can be used for a duration of 2 years.

4. An air volume control valve is installed under each individual grate plate, with the cooling air volume per unit clinker being approximately 1.8–1.9 Nm³/kg.cl.

5. The grate cooler is arranged horizontally, without a 3° or 5° inclination angle, enabling convenient process layout.

6. The speed of both sides of the grate bed is adjustable, effectively eliminating the "red river" phenomenon.

7. A roller crusher is adopted, which requires no maintenance for 2 years and reduces the power consumption of clinker crushing by approximately 40%.

8. The grate bed is supported by rollers, decreasing the lubrication points by 3/4 in contrast to four-link support.